Preface:

In solid waste, residential waste is most common along with industrial exhaust, construction sludge, waste grease, acid, alkali, and sealed gas waste. It is not an easy task to collect these waste of various kinds and monstrous size, let alone to decrease it, make it harmless, and transform it into conducive resources.

With modernization advancing into future and people’s living standard greatly increased, the number of a variety of waste is incremental day by day, posing severe risk to ecological environment. The development of modern industry only aggravated the situation, especially when the advancement of modern electronic information and pharmaceutical chemistry become the main cause of increase in the production of hazardous waste.

|

|

General Solid Waste

|

Hazardous Industrial Exhaust

|

Medical Waste

|

Residential Waste

|

|

2017

(Trillion Tons)

|

13.1

|

0.40

|

0.0078

|

2.02

|

|

2018

(Trillion Tons)

|

15.5

|

0.46

|

0.0082

|

2.12

|

How to effectively solve the problem of solid waste of such magnitude with assorted categories and biochemical hazard?

Traditional landfill is difficult to continue due to the mounting pressure of the size, want of space, long time period and environment pollution. As a result, burning become a much more desirable method. The public concern nevertheless doesn’t go away but shifts to the cost, burning size, production of dioxin and a second damage to environment.

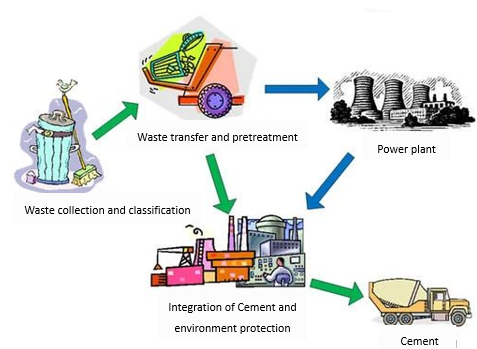

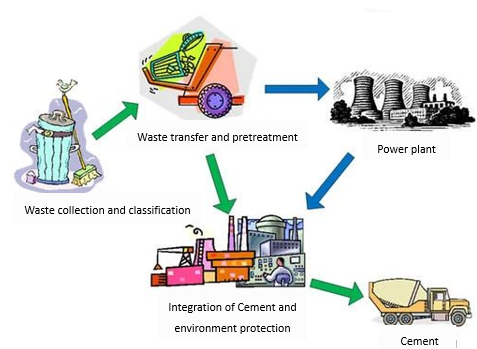

A new measure called co-processing in cement kiln from cement industry requires cement plants to help dispose of solid waste, which is to put qualified waste or qualified waste after pretreatment into cement production to achieve a harmless disposal of the waste by taking advantage of the high temperature, large specific heat capacity, good thermal stability, alkaline environment and no exhaust discharge of the cement rotary kiln. And the kiln can hold gas for a long time. It’s biggest advantages are as following:

l High Temperature

Ø Most efficient and secure

Ø Developed countries started practicing in 1970s and domestic companies in 1990s.

Ø Absolute decomposition

Ø Avoid a second damage by confining toxic, hazardous substance and heavy metals in cement.

High temperature means great advantage in waste disposal. Co-processing in cement kiln will help efficiently confine heavy metal in cement and decompose dioxin and other toxic substance to a high degree without waste discharge through stable combustion.

l Sizable disposal, marginal cost in labor and construction

Ø Inclusiveness: including residential waste, construction sludge and hazardous waste

Ø No waste but substitute for material or fuel

Ø No pollution

Ø Huge potential: 1600 cement production line

As co-processing in cement kiln has been promoted and adopted in a broader area, new regulations Environmental Protection Technical Specification for Co-processing of Solid Wastes in Cement Kiln and Technical Specification for Co-processing of Solid Waste in Cement Kiln come out for the normalization of this measure and protection of environment. These two regulations put a certain limit on heavy metal and other hazardous substance content in solid waste used in kiln. Hence cement plant in this project is required to add a heavy metal test in waste to the normal test process. There will be a separate introduction for waste electricity generation in which test for heavy metal is also demanded.

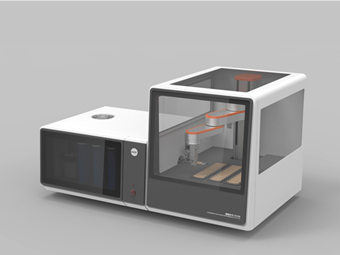

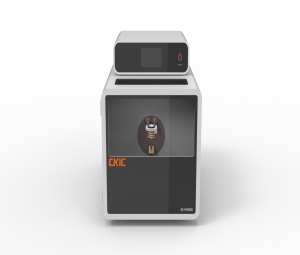

Despite the high precision of ICP, sophisticate pretreatment of the waste is still a problem. Energy Dispersive X-ray Fluorescence Spectrometry (EDXRF) in comparison is quicker and can deliver test result of elements as a whole without loss. EDXRF is the best way to test heavy metal and other inorganic elements content in solid waste. 5E-XRF2500 EDXRF Spectrometer from CKIC therefore is the most desirable choice in achieving these goals.

5E-XRF2500 EDXRF Spectrometer

Process

Pretreatment

Press dry powder sample into a tablet (in vacuum and without consumption of helium). Put moist powder sample or slime directly into Mylar-filmed sample cup and then straight to test.

Calibration

Use various standard sample from GSS, GSR, GSD and prepared sample to create calibration curve in 5E-XRF2500, covering most macroelements and elements in cement kiln.

_340x255.png)

_340x255.png)